Motivation, Maslow & Lean Manufacturing

A Summary of Abraham Maslow's Hierarchy of Needs

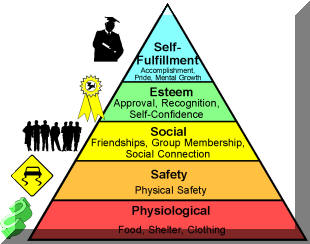

Abraham Maslow's "Hierarchy of Needs" is a simple, effective and practical way to understand normal human behavior. It is a management classic that many of us vaguely recall it from some long-ago study. This article summarizes the original 1943 paper, "A Theory of Human Motivation."

The Five Basic Needs

Maslow suggested five categories of basic needs that are common to all human beings. These categories apply across all cultures, activities, professions and social positions. They are:

Physiological Needs

The physiological needs are those things that keep the body alive and reasonably healthy. Examples are food, clothing and shelter. This is the most basic need of any organism and is at the bottom of the hierarchy as shown in the figure.

Safety

People need to feel physically safe in their environment. In millennia past this meant safe from prowling saber tooth tigers. Today it may mean safety from assault or safety from harmful equipment and harmful chemicals.

Social Needs

Maslow originally used the term "Love Needs" but his description better fits the word "Social". This need involves connections with other people and includes family, group belongingness and friendship as well as romance. All normal people want a place in a group or society, even if they sometimes deny it.

Esteem Needs

With a few pathological exceptions, people need a realistic sense of self esteem and esteem from others. Self Esteem includes honest achievement, feeling adequate to face the world, confidence , independence and freedom. Esteem from others involves reputation, respect, attention and recognition.

Self Fulfillment (Self-Actualization) Needs

Self-Actualization is the most misunderstood of Maslow's categories because of its unfortunate word choice. The ancient Greeks would have called it "fulfilling your destiny." Maslow explains it further at right.

The Hierarchy

The needs are not equal in their motivational power at any given time. They have a hierarchy of "prepotency." This means that lower needs in the hierarchy must be substantially gratified before higher needs become motivators. People who are malnourished, hungry and cold are hardly interested in approval or recognition--they just want food and warmth and they will take serious personal risks to obtain it.

Once the physiological needs are substantially satisfied, people are concerned about safety. They need to feel freedom from violence, accidents or other physical harm. Without this feeling, they have little concern for friendship, recognition or destiny.

When people feel reasonably safe and have the physiological means to sustain life, social needs come into play and so on until self-fulfillment becomes the prime mover for behavior.

The Role of Fear

In the eighth of Edwards Deming's Fourteen Points, he urged managers to "Drive fear out of the workplace" for a very practical reason:

Fear only motivates to minimal compliance.

Once minimal compliance with demands are met, the fear is removed and motivation ceases. Fear does not get the best performance from people. It often brings out unintended and undesirable behaviors.

Physiological and safety needs are largely met in modern societies. Their power to directly motivate mostly ended with labor unions, the welfare state and the liberation of Auschwitz. To some extent, irrational fear can still motivate. For example, fear of losing a job stems from irrational fears of ensuing starvation. such fears, however, are secondary.

The lower needs (physiological and safety) motivate entirely through fear. For some people and to some extent, social and esteem needs are fear-based. Therefore, these lower needs are incompatible with Lean and with high performance. Besides, they never did work very well.

What About Lean?

Effective Lean operations leverage these higher motivators and integrate them with appropriate technologies. The concepts of Socio-Technical Systems play a large role in this.

Teams

Lean Manufacturing makes extensive use of teams. Work Teams, particularly in cells, organize and manage their own work. Quality teams cope with quality issues and improvement teams make processes more efficient, smoother and more capable. Setup teams often work together to improve and speed setup operations.

True teams are not just a group of people who have been thrown together. They are miniature societies with their own mores, codes, procedures and relationships. Teams are excellent vehicles for fulfilling social needs. But they can satisfy even higher order needs as well. Team members implicitly recognize each other's worth and contributions. Members help each other to compensate for each other's weaknesses. Management can recognize teams, rather than individuals and thus promote team solidarity. All of this addresses Social, Esteem and Self-Fulfillment needs.

Cellular Manufacturing

Highly Productive Workcell

Workers in a high-volume assembly cell manufacture brake adjusters for trucks & buses.

The most effective workcells function best with work teams. Teams help to balance work, smooth flow and motivate people. They solve a range of problems and reduce or eliminate the need for supervision. At the same time, a properly designed cell encourages teamwork by allowing easy communication, close proximity and easy movement among workstations.

Various team members will have a range of skills and the team allows those individual skills to be exercised, developed and applied to useful work. the result is a high degree of personal as well as team fulfillment. Workcells carry the satisfaction of higher needs even beyond what teams alone can do.

Quality

Teams have been part of the quality movement from the very beginning. They were originally known as "Quality Circles." Quality, like safety, is an ideal that everyone favors and delivers great personal satisfaction to those who participate in it. Active participation in quality efforts gives people self-esteem and self-fulfillment as they use their abilities to achieve worthy goals.

Process Improvement

Process improvement and quality teams are often synonymous. All of the comments on quality apply here as well.

SMED

Setup Reduction (SMED) often uses teams for actual setups and it uses teams to establish setup procedures and improvements. Active participation can help people to satisfy Social, Esteem and Self-Fulfillment needs as it challenges their ingenuity and skills.

Overall

Training in many skills and areas is an important part of Lean Manufacturing. The idea is to get maximum performance from every employee by addressing the higher needs. The results are highly beneficial for both the organization and for the individual employees.

Abraham Maslow (1908-1970)

A psychologist, Maslow studied what he called exemplary peoples rather than the mentally ill or neurotic. He wrote that "the study of crippled, stunted, immature, and unhealthy specimens can yield only a cripple psychology and a cripple philosophy." Maslow was among the first "humanist psychologists" who focused on normal, healthy ways of coping with life.

Maslow first published his theory in the 1943 and it became a widely accepted notion in the fields of psychology and anthropology. This original article, A Theory of Human Motivation , is available on the internet. He was a professor at Brandeis University. His major texts included Motivation and Personality (1954) and Toward a Psychology of Being (1962).

Maslow on Self-Actualization

"A musician must make music, an artist must paint, a poet must write if he is to be ultimately happy. What a man can be, he must be."

or

"Growth is, in itself, a rewarding and exciting process, e.g., the fulfilling of yearnings and ambitions, like that of being a good doctor; the acquisition of admired skills, like playing the violin or being a good carpenter; the steady increase of understanding about people or about the universe, or about oneself; the development of creativeness in whatever field, or, most important, simply the ambition to be a good human being."

The Human Side of Lean Video

In this unique Lean Manufacturing video, workers explain how they designed and built their own workcell. They talk about benefits to their company, and the profound improvements in their work life as we follow them in their work. These are real people with a real story.

The video dramatically illustrates Maslow's higher motivations as they apply in the workplace and to Lean concepts. It also shows how the human and technical elements of Lean Manufacturing interact in a complex Socio-Technical System.

![]()

References & Further Reading

MASLOW, ABRAHAM, Eupsychian Management, 1965; republished as Maslow on Management, 1998

MASLOW, ABRAHAM, A Theory of Human Motivation (originally published in Psychological Review, 1943, Vol. 50 #4, pp. 370–396).

■ ■ ■ ■ ■ ■ ■